Our CAD design and CAE technology realize precision simulations at the designing and mold trial manufacture stages upstream of production start, and reduce development costs through speedy and accurate analysis using production data fed back from the factory.

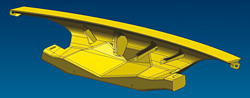

Using the 3D data for the target installation objects received from customers, the company creates the 3D product data. It is based on this that the diagrams for the products are created. In addition, we perform analysis using the created 3D data (airflow, hardness and thickness).

Using the 3D data for the target installation objects received from customers, the company creates the 3D product data. It is based on this that the diagrams for the products are created. In addition, we perform analysis using the created 3D data (airflow, hardness and thickness).

![]()

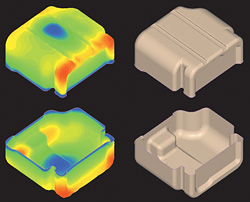

Our CAE is precise technology which is high class in the industry. The AITECH blow molded simulation software, in particular, is in the top class in the world. The blow molded products simulation process is roughly divided into the "mold clamping process" and the "blowing process." The "mold clamping process" displays the melting of the cylinder shaped plastic (called parison) when the mold is clamped. The followup "blowing process" shows the continuous swelling of the parison inside the mold. The ultimate thickness distribution of the molded product is indicated by the difference in color. The product becomes thinner as it changes from blue to green, to yellow, orange and red. Feeding back the thickness distribution data as the standard hardness analysis software input data makes it possible to obtain very high accuracy analysis results.

Our CAE is precise technology which is high class in the industry. The AITECH blow molded simulation software, in particular, is in the top class in the world. The blow molded products simulation process is roughly divided into the "mold clamping process" and the "blowing process." The "mold clamping process" displays the melting of the cylinder shaped plastic (called parison) when the mold is clamped. The followup "blowing process" shows the continuous swelling of the parison inside the mold. The ultimate thickness distribution of the molded product is indicated by the difference in color. The product becomes thinner as it changes from blue to green, to yellow, orange and red. Feeding back the thickness distribution data as the standard hardness analysis software input data makes it possible to obtain very high accuracy analysis results.